Physics of Liquid Contact Line Pinning

Protein crystals are generally grown by dispensing protein-containing drops in 24 or 96 well plastic injection molded plates. Evaporation from the drop increases the protein concentration until, in favorable cases, crystals nucleate and grow. The mechanisms by which they grow are the same as for inorganic and small molecule crystals, although growth rates tend to be small (roughly 1 monolayer per second) and the supersaturations at which nucleation occurs are large (i.e., 4-8, compared with ~1 for, e.g., salt crystals.)

Motivated by our work on pinning in charge-density wave conductors, we have explored the pinning of liquid contact lines on flat and inclined surfaces. Dispensed drops have irregular shapes, and this leads to irreproducible evaporation rates, nucleation and crystallization, and complicates automated inspection of drop contents for crystals.

Contact line pinning by chemical patterning

We first examined drop pinning on surfaces with hydrophobic and hydrophilic patterning. This method increases contact line stability yields more reproducible drop shapes. But chemical patterning is easily contaminated, and does not provide enhanced pinning for all types of protein solutions.

Enhancing drop stability in protein crystallization by chemical patterning. V. Berejnov and R. E. Thorne, Acta Cryst. D 61, 1563-1567 (2005).

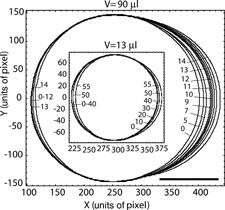

We have examined how the contact line of a liquid drop on an inclined surface depins as the inclination angle increases. Depinning first occurs on the advancing and receding edges, leading to changes in static drop shape of increasing size with increasing angle, until finally the entire contact line depins, leading to drop sliding.

Effect of transient pinning on stability of drops sitting on an inclined plane, Viatcheslav Berejnov and Robert E. Thorne, Phys. Rev. E 75, 066308 (2007).

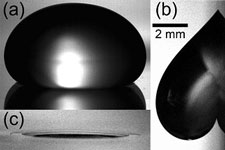

Contact line pinning by topographic patterning

We discovered that micropatterned rings as little as a few microns high and a few tens of microns wide can strongly pin the contact lines of millimeter diameter, microliter to milliliter drops of both soluble and membrane protein solutions. The pinning is extremely robust and does not degrade with time. Drops can easily be rotated to the vertical or inverted without spreading, and drop shape is perfectly reproducible. We have quantified the pinning effect with a wide range of solutions, and have explained its origin. We have also obtained a patent on this technology.

Controlling microdrop shape and position for biotechnology using micropatterned rings. Y. V. Kalinin, V. Berejnov and R. E. Thorne, Microfluidics and Nanofluidics 5, 449-454 (2008).

Contact line pinning by microfabricated patterns: Effects of microscale topography. Y. V. Kalinin, V. Berejnov and R. E. Thorne, Langmuir 25, 5391-5397 (2009).

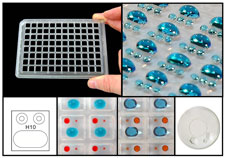

Crystallization plates based on topographic contact line pinning

We have demonstrated and characterized fully X-ray transparent crystallization plates based upon our drop pinning technology. Related designs are being commercialized by MiTeGen, LLC.

Development of high-performance X-ray transparent crystallization plates for in situ protein crystal screening and analysis. A. S. M. Soliman, M. Warkentin, B. Apker and R. E. Thorne, Acta Cryst. D 67, 646-656 (2011).